Hsg76 is the health safety executive guide to warehousing storage and clearly sets out the need for and type of racking inspections required in a warehouse.

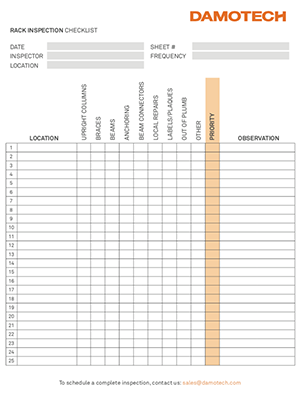

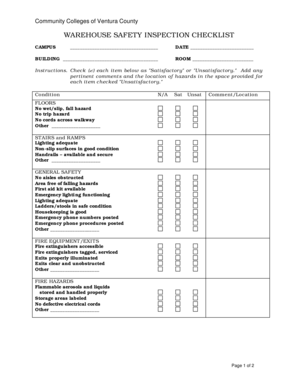

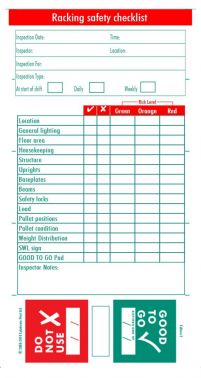

Pallet racking inspection sheet.

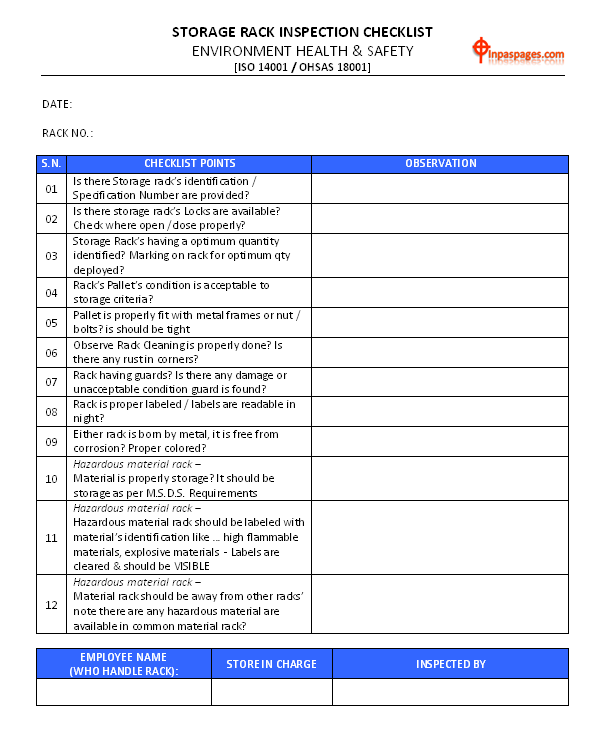

This checklist does not cover every aspect of pallet racking inspections and it is the responsibility of the person s carrying out the inspection to be aware of.

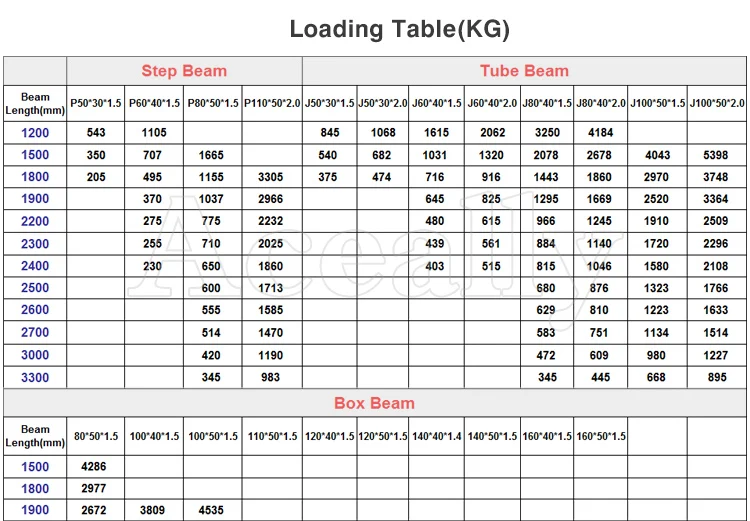

The design of the pallet should take into account the nature of the goods in the unit load.

Goods stored on pallets destined for storage are termed unit loads.

He is an experienced sema approved.

Goods on pallet to be stored in racking.

We have used chris for quite some time now on both small and large scale pallet racking inspections and found his work to be excellent.

Pallet racking inspection checklist.

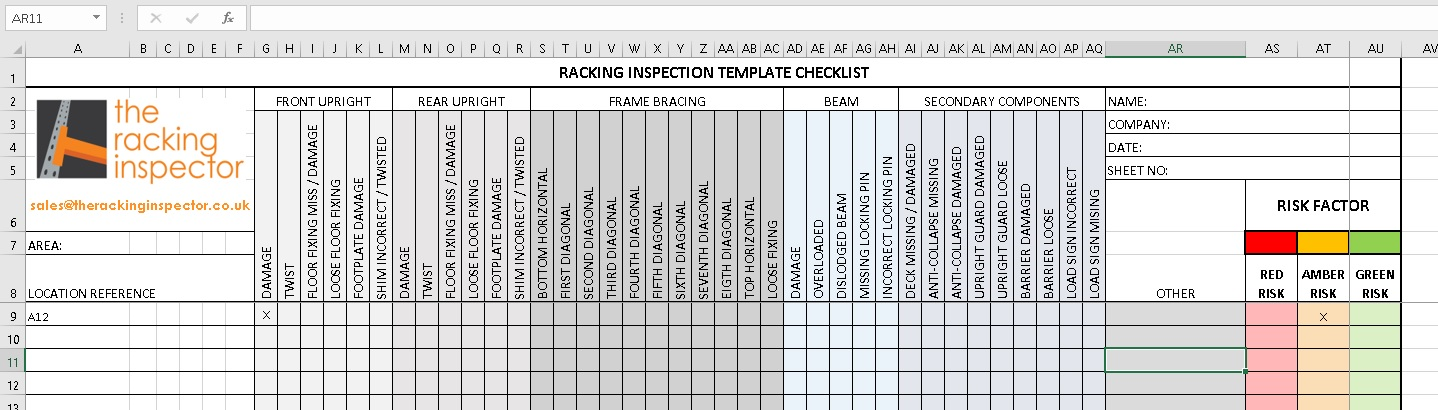

This pallet racking inspection checklist is for general guidance and should be used only by trained and qualified racking inspectors.

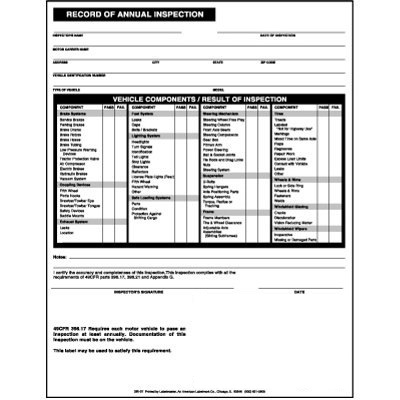

The inspections should be performed by a qualified person familiar with the storage rack design and installation requirements retained or employed by the storage rack system owner.

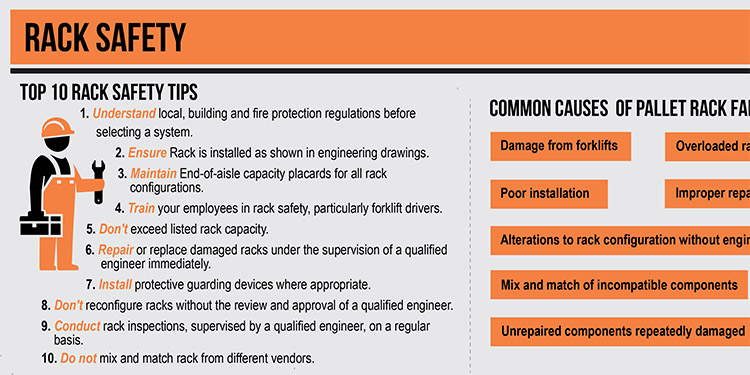

Nothing abuses a rack upright like a forklift impact.

Weekly pallet racking inspection checklist racking inspections shall be carried out on a regular basis and at least every twelve months.

A change in the pallet design should not be permitted unless the.

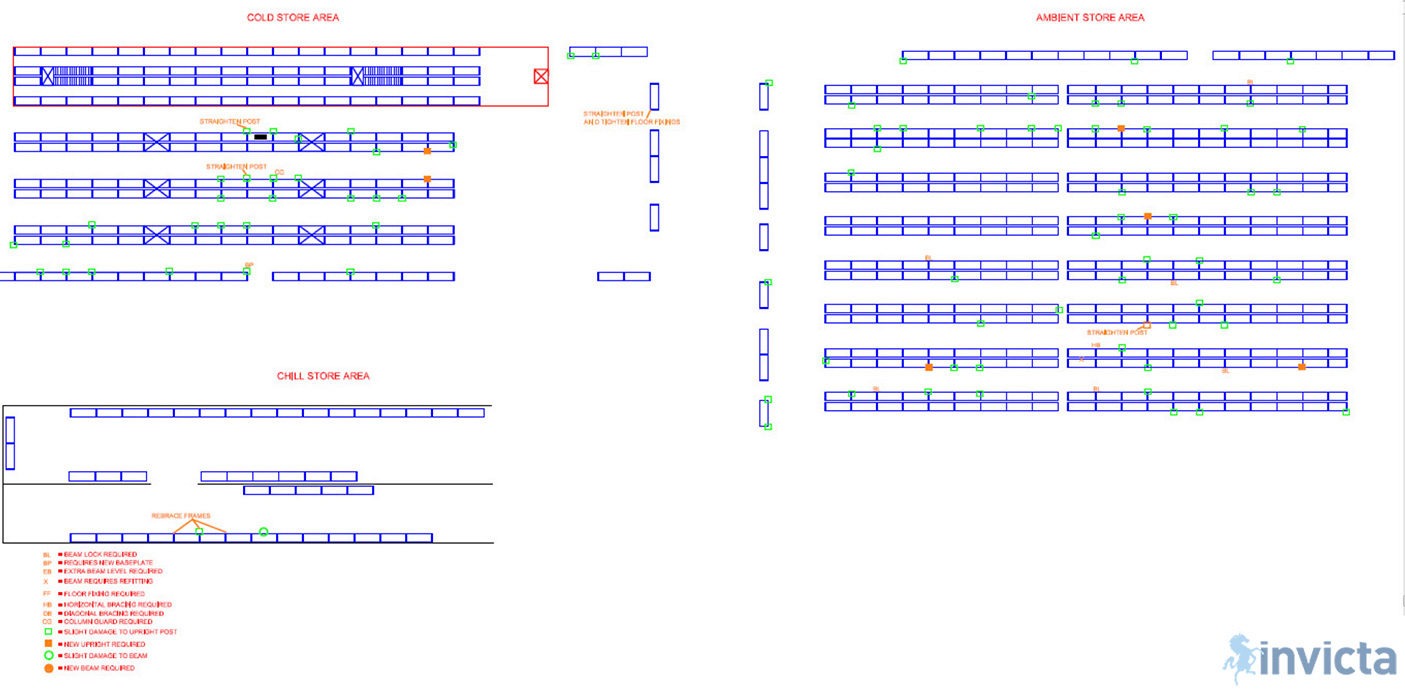

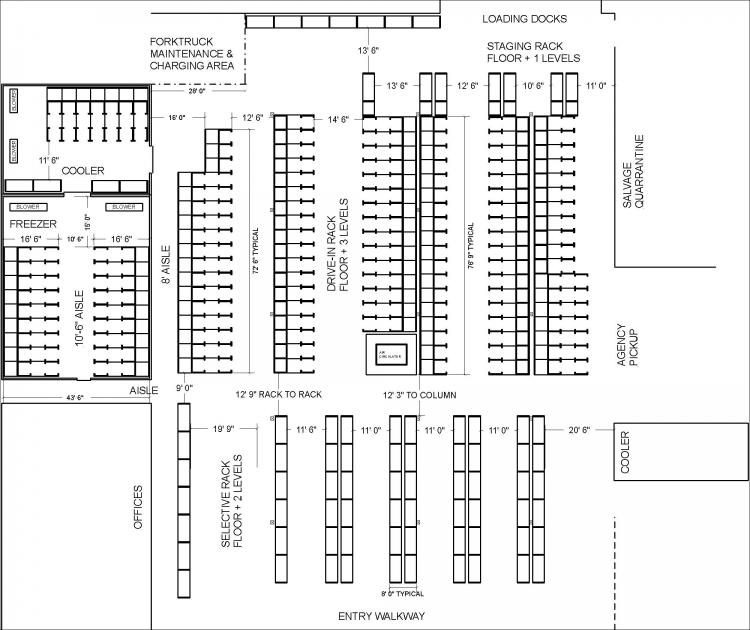

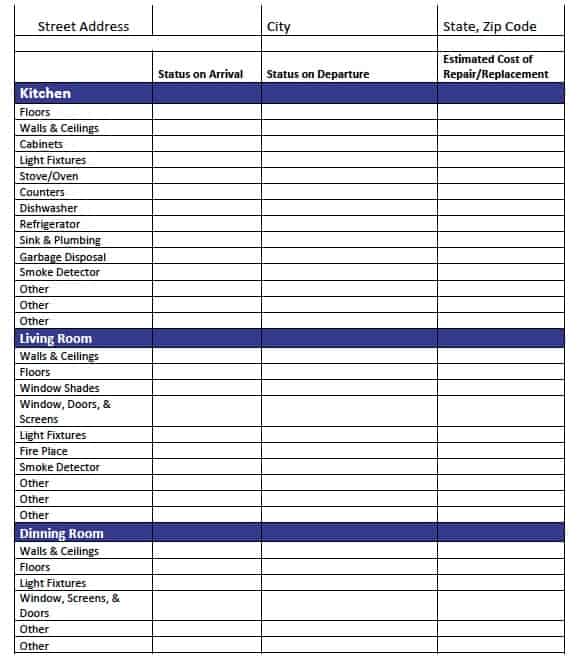

A pallet racking audit is a thorough inspection and evaluation of the condition of the pallet racking in order to identify any damage to the system that may be causing a risk to safety.

Pallet rack inspection checklist employers can use this checklist to help ensure their pallet racks are inspected by a qualified person as per the new storage rack requirements of section 4 43 1 of the occupational health and safety regulation effective january 1 2018.

The employer should establish and implement a program of regularly scheduled storage rack system inspections.

The modern pallet rack is a sturdy workhorse capable of holding its listed capacity as long as you don t overload mis load it smash a forklift into it or otherwise abuse it.

Pallet racking is classed as work equipment under puwer requires regular inspection.

In addition hsg76 sema storage equipment manufacturers association guidelines stipulate that you must appoint a person responsible for rack.

Use the sheet by filling out the location of the damaged component for example.

Regular racking inspections can save you tens of thousands of dollars in potential damages and inventory loss and can even save lives.

Can be inspected and assessed see also inspection of pallet racking below.